Hooked vs Hookless Tubeless Bike Wheel Rims Comparison

Looking into the differences between hooked and hookless rims for tubeless bike wheels digs deep into the very building blocks of a cyclist’s wheel. This examination is meant to explain how these two types of rim are made, what they do, where they can be used with success, as well as why – thereby giving riders a better understanding of which one to choose when setting up their tubeless system in terms of application range and benefits.

Cyclists can categorize features and performance characteristics of both hooked and hook-less rim options according to personal riding style preferences or specific terrain demands, thus ensuring that an informed decision is made about each individual’s needs before making any selection among them. It is important not only to know this but also to comprehend what these various tire fitting, air holding, and general riding experience variations mean in relation to road efficiency maximization while still minding about safety aspects along highways or trails. Such authoritative guidance provides insights into technicalities involved during rim design, enabling cyclists to navigate through different types available on the market today, hence being able to choose rightly based on their bikes’ wheels being tubeless or not.

Understanding Rims Basics

Before we get started, let us first understand what exactly bike rims refer to. In essence, they are nothing more than the outer edges of wheels themselves, supporting tires around them while acting as brake surfaces for those fitted with rim brakes. In addition, rims greatly affect how bikes handle weight distribution as well as overall performance levels under various conditions.

What Is A Bike Rim And How Does It Work?

A bike rim forms the foundation upon which the bicycle wheel rests; it interfaces with either the tube (in traditional configuration) or directly mounted onto the tire (in case of tube-less setup). This component greatly determines things like ride quality, robustness against impacts encountered during rides due gravel roads etcetera so forth – so lighter rims enhance aerodynamics but may compromise strength especially when one is off-road riding where rocks tend to slip under wheels easily thus causing serious damage instead.Crucial parameters here include width; depth; material (commonly aluminum or carbon); design (hooked vs hook less for tubeless tyres). Each factor alters bike’s behavior across different terrains.

Components Of A Tubeless Rim

Tubeless rims are those designed without an inner tube; instead they have a sealed rim bed which has a special valve and tyre setup that holds air. Key parts comprise: the rim itself; a tubeless ready tire; sealant used to prevent punctures from letting out air and also fix them when they occur while riding on rough surfaces like stones etcetera so forth – this being possible because there is no inner tube involved hence allowing for lower pressures which improves grip without sacrificing smoothness over bumps or vibrations.

Going Deeper Into Features Of Hook-Less Rims

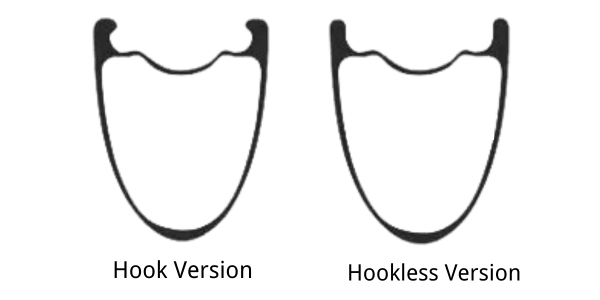

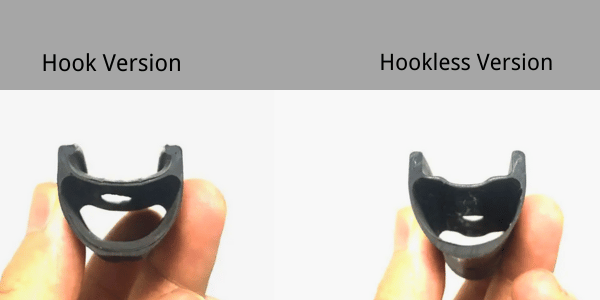

Hook-less rims eliminate the need for bead hooks by extending straight sidewalls from the well of the rim to create a solid connection with tire beads. This design simplifies the manufacturing process, can improve aerodynamics slightly, and allows tight-fitting tyres necessary for setting up reliable tubeless systems across a wide range of off-road conditions, particularly those involving mud or snow, among others.

Merits Associated With Using Hookless Rims

There are several advantages associated with using hook less rims such as: better durability due to fewer weak points along their circumference; superior tyre fitment that ensures air tight seals all round; potential cost savings since these types require less materials during production while still providing same level performance – not forgetting ability run at lower pressures which enhances traction comfort without compromising efficiency even more important if you’re rider who values toughness seamless operation without tubes.

Factors To Consider When Opting For Hook-Less Rims

The significance of bead design in rim compatibility is one area where hookless rims differ from their hooked counterparts. With a hooked rim, the tire’s bead is secured by two hooks on either side; this design allows for easy installation and removal of tires. Conversely, a hookless rim relies on an entirely different mechanism to hold the tire in place – it has a bead shelf that provides more surface area contact with the tire’s bead. This means that when using hookless rims, riders must ensure they are using compatible tires which have been specifically designed for use with them; otherwise, there will not be enough contact between these components and it could result in an unsafe fit or even catastrophic failure whilst riding at high speeds downhill over rough terrain where impacts occur frequently such as rock gardens or roots sections during races like enduro or downhill mountain biking events etcetera

The tire bead design makes a tire compatible with hooked and hookless rims. For the best performance and safety, the tire bead must correspond exactly to the rim’s diameter and profile. Manufacturers indicate which parameters, like elasticity or diameter, they consider important for compatibility. If made properly, the beads create an airtight seal and keep them from slipping off under stress.

Looking into the Advantages of Hooked vs Hookless Rims

We will discuss why different types of mountain biking use either design and what each offers in terms of benefits or drawbacks, etc., so that you can decide based on knowledge gained here about these two options.

Pros Associated With Using Hooked Rims For Specific Riding Conditions

The versatility and reliability features possess by hooked rims are among its strengths. It allows compatibility with many types of tires including tubeless ones. This guarantees a tight sealing system that ensures that tire beads are not unseated during aggressive riding or high-pressure events. In addition to this, hooked rims offer confidence in terms of durability at points where the tire comes into contact with such surfaces because they provide a more secure fit around them than other designs would do so; therefore, they are ideal for cross-country disciplines where sudden stops plus turns are common.

Advantages Of Hookless Rims When Used With Tubeless Setups

A lighter wheel setup with a smoother transition between the tire and rim due to the elimination of a bead hook is possible through the use of hookless rims. Weight ratio becomes maximum while maintaining strength required for fast riders which makes it suitable especially those who prioritize speed over everything else while riding their bikes downhill or flat terrains alone without any obstacles coming their way within sight distance next few meters ahead only if necessary otherwise move straight towards destination without much effort being put into pedaling too hard since there’s no need anyway considering how easy should be coasting along even if going up slight incline because gravity does most work anyhow but still try not to lose control over bike completely so as avoid crashing into something on road surface like car tire accidentally left lying around by careless driver unaware hazards created thereby posing a risk to life and limb.

Understanding Tubeless Standards And Their Influence On Rim Selection

Tubeless systems have revolutionized cycling by reducing flat tires, increasing traction, and providing a smoother ride. Certain factors need to be considered when choosing between hooked or hookless rims for tubeless applications.

Review of common tubeless standards in the industry

The UST (Universal System Tubeless), TLR (Tube-Ready), and 2Bliss are some of the most widely recognized tubeless tire standards used in the cycling industry. Each standard has its requirements for sealing systems; for example, UST can achieve an airtight bead lock without using sealant, while both TLR and 2Bliss need sealants applied so they may function properly. These variations also affect air retention rates, ease of setup, and overall durability levels, which should be considered before selecting any type or brand of tubeless tires.

How rim design affects meeting tube fewer sealant demands

The effectiveness of a tubeless setup relies heavily on the design of the rim bed. This is because it determines how well sealant will be distributed throughout, preventing air loss through porous areas within them. This could lead to weak points where punctures occur frequently during rides, thus affecting longevity negatively if not addressed properly at the early stages. The hook part on hooked rims needs to tightly hold onto the tyres in order maintain sealing while for those without hooks rely diameter matching between these two parts during manufacturing process hence better performance expected if all parameters considered right from beginning till end

Frequently Asked Questions

Q: What’s the difference between a hooked rim and a hookless rim for tubeless bike wheels?

A: Hooked rims utilize a bead hook to hold the tire in place, while hookless rims rely on the tire's bead lock.

Q: When it comes to compatibility with tire beads, how are hooked rims different from hookless rims?

A: Hooked rims are made for use with clincher tires; unlike this, hookless ones can fit a wider range of tire beads.

Q: Why should I use hookless rims for tubeless bike wheels?

A: This is because they allow lower tire pressures, increasing grip and comfort when riding on rough surfaces such as gravel or cyclocross courses.

Q: Can I use hookless rims with high-pressure road tires?

A: Most models of these types of wheels are designed for low-pressure applications, but some newer versions can be used with higher-pressure road tubeless setups.

Q: Which type of wheel do you typically find carbon fiber —hooked or hookless— used for tubeless setups?

A: Carbon wheels are often made without hooks to maximize their strength and stiffness properties, enhancing performance.

Q: How does internal rim width affect whether I choose hooked over hook-less rims?

A: Wider tires work better on wider rims because they have more contact patch area due to lower pressure requirements. However, narrow road racing carriages may still need hooks for higher pressures even though such situations would be rare.

Q: Why is there an ongoing discussion about using hooked or hook-less rims in road and gravel cycling events?

A: The safety standards set by some manufacturers demand that only hooked designs should be used while others support any kind of innovation which could enhance rider experience.