Clincher vs Tubular vs Tubeless: Which Tire is your Best Choice?

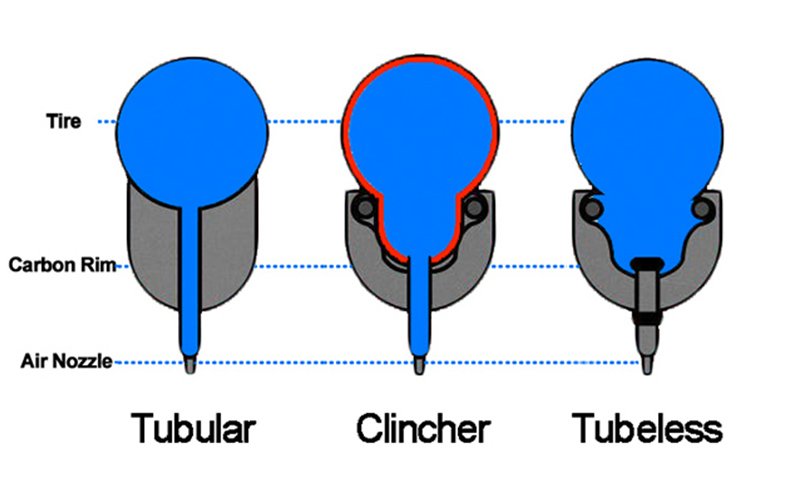

It is vital to optimize performance, safety, and enjoyment by choosing the perfect tire for a bicycle, including clincher, tubular, and tubeless ones. Construction, usage objectives, and compatibility with different wheelsets influence tire types' strengths and weaknesses. This dramatically affects performance while riding, handling, and maintenance; hence, cyclists need to be acquainted with the subtleties of each alternative.

The main aim of this essay is to unravel the differences between clincher, tubular, and tubeless tires, thereby providing basic knowledge that enables cyclists to make choices based on their preferences, where they ride, and what they want to achieve. Riders can, therefore, choose the most suitable option by examining the technical aspects and practical applications of each kind of tire to improve their cycling experiences.

Image source: https://bestwheelset.com/clincher-vs-tubular-vs-tubeless-which-tire-to-choose/

What are the primary distinctions between clincher, tubular, and tubeless tires?

Selecting the correct tire for your bike entails knowing the crucial characteristics that distinguish clincher, tubular, and tubeless tires. Every type has its unique construction, installation process, and performance parameters, which affect your riding experience depending on where you ride and your personal choices.

Construction and Design Features

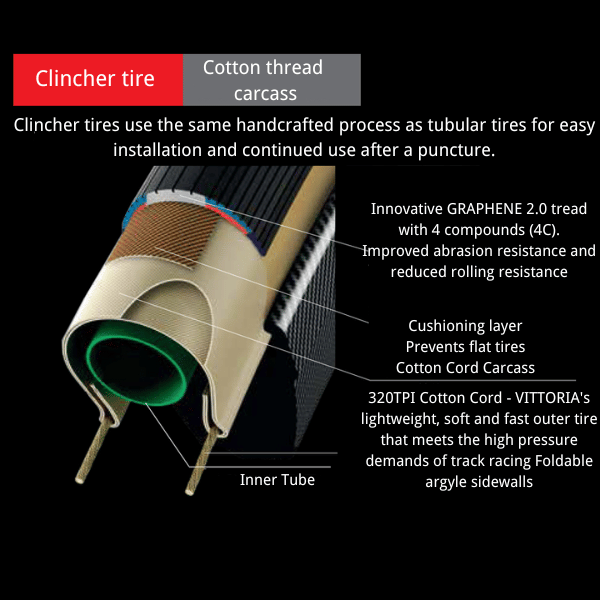

Clincher Tires are the most common type of bike tire. They have a bead that enables them to fit over rims, holding them in place. A separate inner tube is enclosed within the tire to maintain air pressure, making it easier for users to set up or replace clinchers.

Tubular Tires: In contrast with clinchers, tubular bicycle wheels are closed tubes that have been stitched around an inner tube. The tires are then glued/taped onto rims specially designed for this purpose. It allows for a seamless connection with the rim so that one experiences smooth rides with no chances of “pinch flats.”

Tubeless Tires: Inner tubes need not be used since tubeless seals directly against an airtight rim. Besides having sealant inside the tire that fixes punctures, this type offers lower rolling resistance and allows one to use lower air pressures, thereby improving traction.

Installation Process Comparison

Clincher Tires: This involves placing a tire on a rim, fitting an inner tube inside it, and securing the tire's bead into place by using a tire lever. The process is pretty simple and can be done without help from professionals.

Tubular Tires: Installation here needs more work than other types since care should always be taken when gluing or taping down such tires on rims. It may appear difficult for beginners, hence the need for professional assistance to ensure attachment security.

Tubeless Tires: You place the tire on the rim, add sealant, and then inflate the tire to seal against the edges. Initially, this can be a bit difficult as an air compressor may be necessary to tighten everything.

Performance on Different Types of Bikes

Clincher Tires: Due to their convenience, availability, and versatility, they are suitable for most road bikes, mountain bikes, and everyday commuting bikes.

Professional road racers and competitive athletes prefer Tubular Tires due to their performance merits, which include less weight and fewer chances of flats. Still, they are not well-suited for casual riding.

Tubeless Tires: These favor more off-road riders seeking lower air pressures without pinch flats, improved traction, and better performance. However, they require compatible rims and some care.

Which Type of Tire Offers the Best Puncture Resistance?

This decision will significantly affect your bike usage, especially when avoiding flat tires. Each type, from clinchers to tubeless, has its own set of features contributing to their puncture resistance. This information is crucial in choosing based on your cycling preferences.

Impact of Tire Construction on Puncture Prevention

When making a tire, its resistance to puncture can be affected by how it’s built. Puncture resistance in clincher tires is average and depends mainly on the tire's thickness and the inner tube's quality. Tubular tires have more puncture protection due to their seamless construction, and gluing them to the rim gives an extra defense. However, in terms of puncture resistance, tubeless tires take the day. The absence of an inner tube and the use of a liquid that seals within the tire not only plug up punctures almost instantly but also allow for thicker and more robust tire compounds, which are less susceptible to being pierced in the first place.

The Effective Use of Sealants Across Different Types

Sealants are essential in improving puncture resistance for tires, primarily tubeless ones. They can also be used as sealants inside specially designed inner tubes for sealant-compatible clinchers, providing another line of defense against flatting. Although sealant may also help for tubular, adding it is relatively cumbersome, given how many tires are manufactured. As opposed to other types, these tires were meant to be used with sealant included in them. This type seals holes immediately as they form, preventing most flats from common thorns.

Flat Tire Repair Methods Compared Amongst Each Type

Different types differ regarding ease or effectiveness when it comes to repairing flats. Changing or patching the inner tube makes clinchers relatively easy to fix when stranded on the side. Being glued on tubular presents a more significant challenge, thus nearly impossible roadside repair that often necessitates complete tire replacement instead. Tubeless tires have an advantage since small ones can self-seal off using a liquid sealant. In contrast, bigger ones could easily be patched with a plug kit, thus avoiding immediate tire replacement or resorting back to tubes.

By understanding these aspects concerning tire selection and maintenance, cyclists may better prepare themselves for their riding adventures, reducing downtime and maximizing pleasure.

Are clincher, tubular, and tubeless tires different regarding rolling resistance and traction?

Rolling resistance and traction are important factors impacting a cyclist’s speed, efficacy, and safety. Clincher, tubular, and tubeless tires have different properties that affect these aspects in varying ways to shape the cyclist’s experience and performance.

What Influences Rolling Resistance in Different Types?

The rolling resistance of any tire is influenced by several factors, such as the material used to make it, its tread pattern, the presence or absence of sealant together, and the type of sealant. Clincher tires have a relatively high rolling resistance due to their construction design, which requires another inside tire, hence increased friction. Tubulars, on the other hand, feature low levels of rolling resistance because of their smooth, seamless format, which aids in gluing them onto rims, making them easier to ride. Among these three types, this is further helped by tubeless ones that lack inner tubes but can operate at lower pressures without fear of pinch flats having the lowest levels of rolling resistance. Besides filling minor irregularities in the tire surface that reduce energy loss, these substances also allow for uniformity within the tire case, thus avoiding extra tread damage.

Analysis of the Traction Levels on Various Terrains

An excellent traction difference among different types of tires affects handling and stability depending on the conditions. Clincher tires can be easily adjusted by changing their pressure or pattern to provide reliable traction for various situations. As they can take on shape even at lower pressures, tubular tires have superior traction when used on smooth surfaces like asphalt. Tubeless tires perform well off-road due to their low pressure, which expands the contact patch and, hence, grip over rough terrain.

Role of Tire Pressure in Optimizing Rolling Resistance and Traction

Rolling resistance and traction should be balanced through the driver's tire pressure control. Less pressure would lead to less rolling resistance on soft grounds, as these enable greater conformity with the surface; however, this parameter may increase due to more friction as larger sections come into contact with more complex surfaces. On challenging terrains, higher pressures decrease the contact patch size, reducing rolling resistance while limiting traction by reducing adherence between the tire and the surface it runs over. There is also a high risk of pinch flats, requiring clinchers and tubulars to be run with higher air pressures. At the same time, tubeless tires are set below them to optimize both factors across diverse settings.

Maintenance Considerations for Tubeless, Tubular, and Clincher Tires

Tubeless, tubular, and clincher tires require proper maintenance for better lifecycle performance and safety. Each type has its own way of keeping them in optimal conditions to make cycling experiences more enjoyable.

Guidelines for Replacing Sealant/Checking Tubeless Tire Sealant Level

Sealant is an essential part that stops air loss and seals punctures in tubeless tires. It needs checking every 2-3 months, just like when it dries up or reduces in volume significantly and requires replacement. A small dipstick inserted after removing the tire valve core can be used to check the sealant level. If the stick is dry, there is insufficient sealant, and more should be added. Typically, 30-60mls of such liquid is enough for a regular road tire, while twice as much may be needed for mountain bikes.

Inspecting and Regluing Tubular Tires for Prolonged Use

Since tubular tires are glued or taped onto rims, they must be checked periodically to ensure they remain in place. Check the bond every few months or if you have been exposed to excessive heat or moisture by trying to shift the tire on the rim gently. Once any movement has been detected or when the glue starts deteriorating, it will be essential to remove all old adhesive material, cleanse both rims together with the tire base, and finish off with new layers of glue for the tires. A firm tire grip will prevent it from rolling off during use.

Best Practices for Maintaining Rim Integrity in Tubeless Setups

Safety, as well as the performance of tubeless setups, heavily relies upon rim integrity. Crack presence on the rims should always be looked at as this might lead to dents on tire seals. Moreover, one should ensure no loose ends between seats occupied by rim tape because these tend to cause air loss from these rims. If damaged, replace immediately using the correct width and apply smoothly without wrinkling or doubling up where appropriate; also, check the valve so that it does not get blocked, ensuring a tight connection.

Frequently Asked Questions

Q: What are the critical differences between clincher, tubular and tubeless?

A: Clincher tires commonly contain an inner tube to hold air, while tubulars are seamless and bonded directly to the rim. On the other hand, tubeless tires don’t have inner tubes but rely on a sealant to maintain air pressure.

Q: Can clinchers and tubular be more durable than tubeless wheels and tires?

A: Cyclists prefer using tubeless wheels and tires because they are less prone to pinch flats and can fix small punctures, thus enhancing reliability in rough terrain.

Q: May clincher wheels use tubeless tires?

A: To ensure proper sealing and performance, you must avoid fitting standard clincher rims or wheels with tubeless tires, which may result in air leaks and poor performance.

Q: Are there any advantages to tubulars over these options, such as clincher/tubeless?

A: Professional racers also choose tubular wheels due to their lower rolling resistance and ability to run at low tire pressure. These give smoother rides when the rider tackles uphill tasks requiring extra power.

Q: How do these two designs' convenience and maintenance differ?

A: Tubeless tires are easy to mount or remove compared to tufted ones, which involve a long process of gluing the tire on the rims. Furthermore, a rapid sealant action can be performed on a tubeless tire in case of any minor puncture.

Q: Can I inflate them using a standard air compressor?

A: However, it is essential not to put excess pressure above the limits provided by manufacturers if one decides to use an ordinary air compressor because it can cause tire damage or even explode off their rims.

Q: What type of tire should I get for my disc brake road bike?

A: Lower pressures for greater comfort and increased traction levels, especially when riding on bumpy or wet roads, make many cyclists opt for tubeless tires for their bikes with disc brakes.

References

——

Academic Journal on Material Science: A paper about the materials used in tire fabrication and how they can affect their performance. This source might explain why certain materials are preferred for different kinds of tires and how these choices influence durability, weight, and rolling resistance.

Cycling Performance Study: A peer-reviewed study comparing the performance of clincher, tubular, and tubeless tires in various racing conditions. It will provide numerical data concerning speeds, grip levels, and puncture resistance, hence helpful to competitive cyclists.

Manufacturer's Technical Guide: Exhaustive manuals by leading brands of tires detailing features of their clincher/tubular/tubeless tire designs. These sources are crucial for understanding the company’s proprietary technology and innovation associated with its products.

If you have any questions about carbon wheels and rims, please feel free to reach us at carbonbikewheel@aliyun.com. Furthermore, you can view the following pages to know if there is one that suits your needs.