Exploring the Pros and Cons of Hub Motors for Electric Bikes: Understanding the Advantages and Disadvantages

The Benefits of Hub Motors

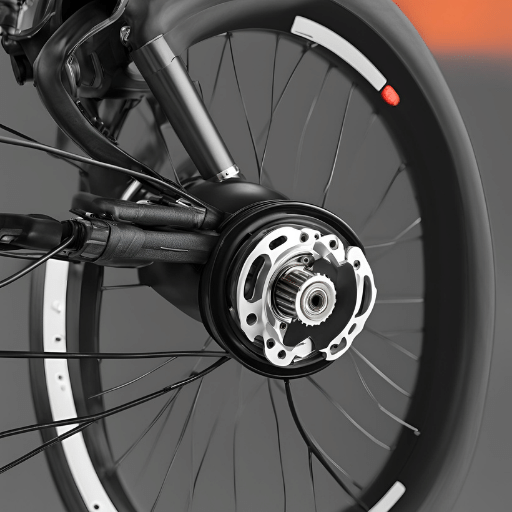

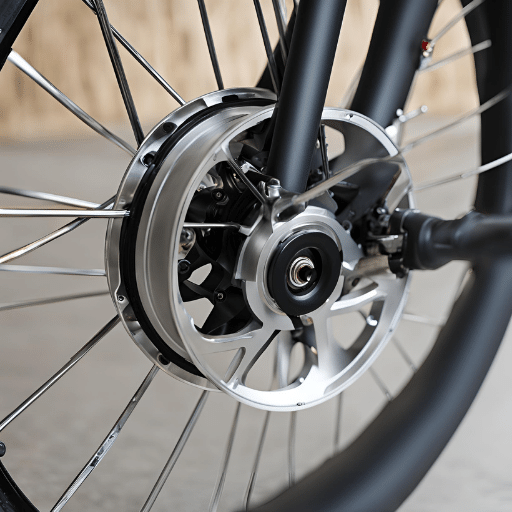

Electric bicycles are frequently equipped with hub motors which have a number of advantages that can improve the experience for riders. Firstly, in comparison to mid-drive motors, hub motors are generally easier to install and maintain. This is because they have been designed in such a way that the motor is part of the wheel hub itself, so there is no need for other drive chains or gears. Also, they run quietly therefore ensuring that one has an enjoyable ride without any noise disturbances. In addition to this, another benefit offered by them is seamless gear shifting due to their non-interference with the existing drivetrain system of the bicycle, thereby providing smooth power delivery without causing extra wear on different parts involved. Moreover, durability and reliability are among other things well-known about hub motors, considering that they require less frequent servicing and perform better in various weather conditions than many other types of electric bike motors do. These characteristics combine together making it very attractive for a lot of e-bike lovers.

Why Go for a Hub Motor for Your E-bike?

Comprehending the Essential Benefits of Hub Motors

When talking about hub motors for electric bikes, it is important to consider their unique advantages. These types of motors are known to have a simple installation process that eliminates all the troubles that come with mid-drive systems. This makes them perfect for people who want low-maintenance solutions. Additionally, hub motors work independently from the chain and gears of the bike, which reduces mechanical wear as well as allows for smooth, uninterrupted gear shifting. In terms of performance, they provide quieter operation and more consistent power delivery thereby making your ride seamless. Being naturally durable also means they can be used under different environmental conditions with little maintenance required. Moreover, various power outputs are available in case you need different sizes for casual commuting or tough terrains. Hence, a friendly set-up coupled with minimum care features makes hub motor so popular among many e-bike riders.

Comparison between Hub Motor vs Mid-Drive Motor: Which One Should You Choose For Your E-Bike?

There are several factors that should be considered when choosing between a hub motor and mid-drive motor for your electric bicycle.

Power Delivery Efficiency: Gearing systems help maintain better efficiency levels, especially in hilly areas, thus making mid-drive motors more efficient than hub counterparts in general; this also renders them suitable for mountain bikes or off-road cycling where lots of climbing is involved. On the other hand, flat lands or urban commuting require constant power output; hence, the preferred choice would be either a front wheel drive or a rear wheel drive system, such as one powered by a geared hub motor.

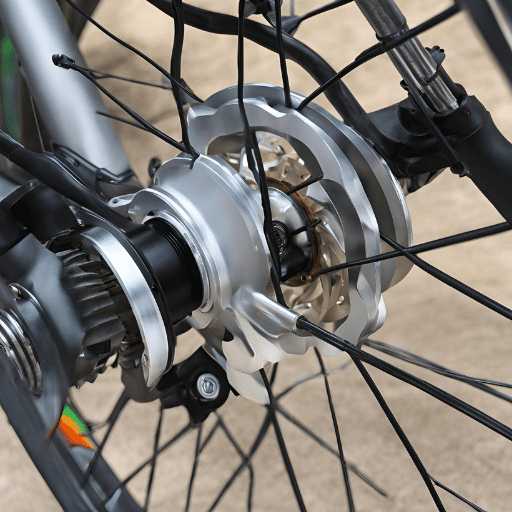

Weight Distribution & Handling: A centralized positioning within the bottom bracket area improves balance as well as weight distribution through the down tube, but closer proximity towards the rear wheel axle creates a natural feel while riding downhill, therefore increasing stability during high-speed descents.Mid drive systems also tend to provide better-handling characteristics due centered location whereas placing additional weight onto wheels may affect maneuverability even though it could make changing tires difficult in case of the hub motor.

Maintenance & Durability: Hub motors are designed with less maintenance in mind since they operate independently from chains and gears. They are also less prone to damage as a result of external impacts. Drive units, on the other hand, can be more delicate because their integration into the bicycle's drivetrain exposes them to higher level strain, thus requiring frequent servicing, especially if ridden under heavy load conditions or over rough terrains that may cause chain slap against rear derailleur cage which eventually leads to premature wear out of both components (chain+rear derailleur).

Installation Cost: Most hub motors have a simple design and an easy installation process compared with mid drives, which involve removing the bottom bracket and then re-fitting it after mounting the drive unit onto the frame, hence making it a bit complicated for some individuals who don't like too many steps during the assembly process. Although installing a mid-drive motor may take longer time than fitting a hub motor, this type of system offers increased performance levels over what is achievable by just having a front wheel-driven hub motor alone.

In conclusion, whether you go for a hub motor or mid-drive will depend on your specific riding style requirements.For light riders who do not need high speeds but want reliability on flat terrains, then hubs are best. Conversely if one wants smooth power delivery all along various gradient changes when riding off road trails where there’s high amounts climbing involved; then mids would be better suited for such applications.

How Hub Motors Improve the E-Bike Riding Experience

Many prominent qualities have been introduced into the e-bike riding experience by hub motors. Firstly, they ensure smoothness and silence in operation which makes rides enjoyable without being noisy like mid-drive systems in some cases. Installing hub motors is relatively easy hence quick set up with less trouble. Their location within the wheel also helps stabilize an e-bike thereby giving even power delivery over flat grounds or when accelerating from stops during city rides. Moreover, maintenance needs for these devices are generally low since their enclosed design protects against wear and tear as well as other external damages. In this way, such motors guarantee reliability alongside user-friendliness while riding, which makes them a common choice among many electric bicycle lovers.

The Technical Advantage: Hub Motors in Electric Vehicles

Revolutionizing Electric Cars through the Employment of Hub Motors

Hub motors have many roles in revolutionizing electric cars because they have several benefits. Chiefly, instead of using a motor that is separate from the wheels, hub motors incorporate the motor directly into them, thus eliminating the need for complicated transmission systems. This saves space significantly and enables more flexible designs of vehicles. They also serve to improve efficiency by cutting down on mechanical losses associated with traditional drivetrains. Additionally, they offer better handling and stability through improved weight distribution as well as independent wheel control, which is necessary for traction and safety. Normally less complex in structure than other types of motors, hub designs require comparatively low levels of maintenance. Moreover, fewer moving parts mean reduced chances of mechanical breakdowns, leading to higher dependability rates. These features are among those that are fueling the widespread adoption of hub motors in next-generation EVs, heralding a paradigm shift within automotive engineering.

Discovering Gears and Torque Dynamics In Hub-Motors

Hub motors do not typically need extra gears since they can convert electrical energy into mechanical motion at their wheels without any assistance; hence this configuration greatly simplifies powertrain systems while minimizing energy wastage. The torque dynamics exhibited by these devices are particularly efficient due to their direct connection with wheels, which ensures instantaneous delivery of force throughout all levels, thereby giving consistent performance across different speed ranges. With instant torque available even at very low speeds, hubs provide excellent acceleration and responsiveness – qualities much needed by city drivers where stop-start traffic dominates most routes. By doing away with intermediate mechanical components found in conventional driveshafts (such as universal joints), hubs achieve higher overall efficiency, thereby saving power consumed during operation and enhancing vehicle behavior on roadways worldwide. Such straightforwardness not only simplifies mechanics but also results in quieter rides coupled with smoother operations, making them ideal choices for modern electric automobiles.

Advantages and Disadvantages: A Balanced Outlook

Balancing the Good and Bad: Mid-Drive vs. Hub Motor

There are many things to consider when deciding between mid-drive or hub motors, as these two systems have their own strengths and weaknesses that are created by a number of factors:

Pros of Mid-Drive Motors:

- Efficiency and Performance: Usually, mid-drives have higher efficiency rates than hub models. They can keep the best motor performance across a range of speeds and terrains by working with the bicycle’s gears.

- Weight Distribution: These motors are positioned in the center of the bike which results in a more balanced weight distribution throughout it. This feature improves stability, especially on difficult surfaces, while also benefiting handling.

- Torque Production: For climbing steep hills or riding off-road, they produce more torque due to gear utilization. At the same time this allows for better acceleration and overall performance too.

Cons of Mid-Drive Motors:

- Complexity and Maintenance: Installation process may be more complicated than with hubs; besides there is need for integration into drivetrain which makes them harder to maintain compared to other types like those based on wheels.

- Cost: Higher cost because mid-drive systems employ advanced technologies along with additional parts required so that they can work properly together.

- Increased Wear: Chain and gear system wears out faster when using this type of motor hence one has change them frequently otherwise everything else will fail soon thereafter.

Pros of Hub Motors:

- Simplicity: There is no need to worry about gears since hub motors work independently from them thereby reducing complexity within drive train system as whole . In addition fewer moving parts means less chance for mechanical failure too.

- Lower Maintenance: Less servicing is needed due to fewer components involved, thus leading to low repair costs incurred over time.

- Cost Efficiency : This cheaper option among two alternatives, hence being the favorite choice among people who are budget-conscious about what they spend on e-bikes at entry-level categories mainly designed for beginners.

Cons of Hub Motors:

- Weight Distribution: These motors located at hubs may cause uneven weight distribution which can affect maneuverability thus making it difficult to handle especially when riding through corners or tight spaces .

- Efficiency in Challenging Conditions: Inability to adjust torque and speed as effectively mid-drives do makes hub models struggle with steep inclines and off-road conditions where they react less efficiently than their counterparts.

- Heat Dissipation: While being used continuously for long periods of time some may face overheating problems because there are not enough ways how heat generated during operation could be dissipated properly hence leading reduced performance levels over a certain period of usage .

In conclusion, the decision between choosing a mid-drive over a hub motor depends on what the rider wants. Mid-drives are best for versatility and power output but this comes at an increased cost as well as higher maintenance requirements. On the other hand, hubs offer simplicity along with affordability; however, they lack in terms of handling under demanding conditions.

Effect of Hub Motors on Weight Distribution and Bike Handling

The weight distribution of an e-bike is significantly impacted by the placement of hub motors within its wheel hubs. This central position results in a heavier wheel, which may affect bike handling in various ways. First of all, steering becomes less responsive and more difficult due to the added weight at the wheels, especially when riding slowly or making sharp turns. Consequently, such a bicycle loses some general maneuverability making it less nimble compared to mid-drive models.

Moreover, balancing is altered by unevenly distributed weight caused by the hub motor; thus riders will have different feelings while riding this kind of bikes particularly during acceleration and deceleration processes. In addition, rotational mass increases gyroscopic effect that stabilizes the bike as speed increases but makes it harder to change direction quickly.

Furthermore, if only one wheel has been motorized, suspension performance might be affected negatively because off-balanced loads are applied onto them hence leading to asymmetrical load distribution whereby one side carries more than another side carries with respect to ground contact points (these loads could be different). Such a situation can result into reduced traction and handling abilities when riding off-road or over rough terrains.

In conclusion, even though simplicity and cost are benefits brought about by hub motors, they also bring along challenges related to weight distribution and handling, which should be taken into account by riders depending on their intended use and style of riding.

Different Kinds of Electric Bicycles with Hub Motors

Why are Hub Motors Better Suited to Electric Mountain Bikes?

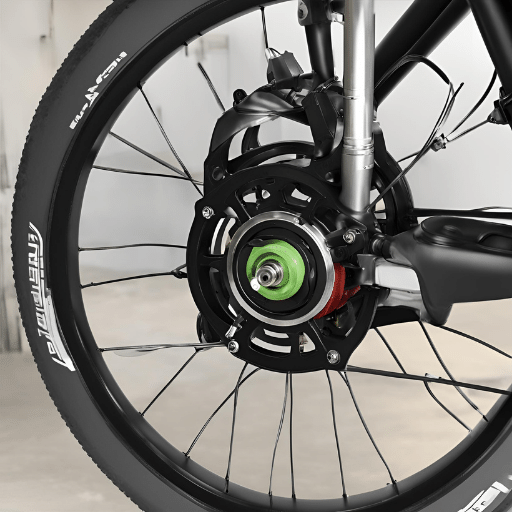

It is true that there are several benefits of using hub motors in e-MTBs. These pluses come from the fact that they have simple designs and operate efficiently. Typically, they are stronger than mid-drive systems and less susceptible to breakdowns because they contain fewer moving parts which may fail mechanically. Such durability is quite significant when it comes to mountain biking as it takes place in rough terrains.

Another major benefit is their low maintenance requirements coupled with ease in servicing them regularly. Unlike other types of motors, hub motors do not put direct stress on the bike’s chain and gears hence this makes such components last longer before replacements become necessary. Therefore, riders end up saving a lot on continuous repairs over time.

In addition to this quietness feature also matters a lot especially when riding through serene environments such as those found along trails used by MTBs. With such engines one can ride without getting disturbed by noise pollution thereby enabling him or her to enjoy the surrounding nature more while still covering longer distances within a given period.

Moreover, another key area where these motors excel performance-wise has got something to do with power delivery, which remains uninterrupted throughout different speeds, thus making them ideal for climbing steadily up hills or covering vast mileage on various types of tracks usually encountered during mountain biking activities. This regularity enables cyclists’ bodies to conserve much energy needed, especially when tackling difficult routes, since it helps maintain momentum even under tough conditions, thereby preventing frequent stops due to fatigue.

To sum it all up: their toughness; convenience in terms of maintenance requirements; silence during operation and smooth power delivery make hub motors better than any other drive for electrically powered bicycles designed specifically for use in mountains by people who need machines that will never let them down while riding through rough places full surprises.

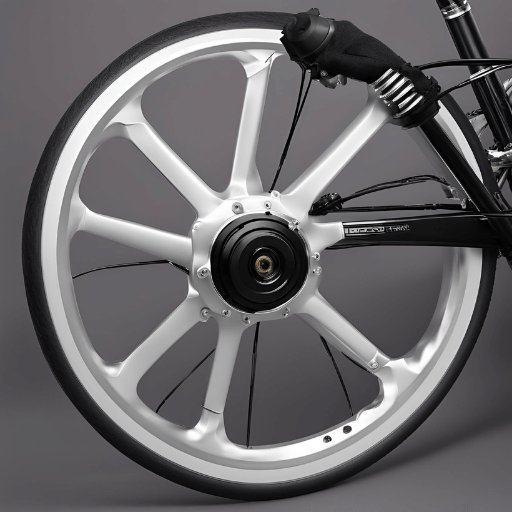

Why E-Bikes are Revolutionized by Geared Hub Motors

The reason why geared hub motors are transforming e-bikes is their efficiency and adaptability. These sorts of engines utilize planetary gears that can create more torque at lower speeds without increasing the size of the motor, thus being perfect for off-road adventures or city commuting. What this means in practice is that you have a smaller and lighter bike, which gives you a much smoother ride while still keeping control over it. Moreover, one thing about those motors is that they use up battery power very effectively — this extends the range of an e-bike so you could travel further on one charge. In addition to all these benefits, a regenerative braking system can be implemented into such engines which will save energy by converting kinetic energy back into stored electric power. Also, these kinds of motors require little maintenance and work well on different terrains like mountains or plains so reliability isn’t an issue here either; therefore, if you want your electric bicycle to have power as its middle name while also being reliable enough for day-to-day use no matter where ever it takes place — then go with geared hub motor!

Breakthroughs in Hub Motor Technology

Newest Innovations in Wheel Hub Motor Systems

Current improvements in wheel hub motor systems have markedly enhanced its performance, efficiency and integration into electric mobility solutions. These include the integration of advanced materials such as high-strength alloys and composites which cut down weight and increase durability at the same time. Real-time monitoring and optimization of motor performance across different terrains and riding conditions is made possible through smart sensors and control systems that have been incorporated within the system. Additionally, better thermal management systems have been introduced to effectively dissipate heat energy, hence preventing overheating and increasing the life span as well as the reliability of the motors.

Furthermore, modular hub motor designs that have emerged recently ease maintenance since they allow for easy replacement or repair whenever necessary. This can be done by anyone who has little knowledge about them. Too much expertise is not needed here. Dual-motor systems development where both front/rear hubs are used provides more grip, especially on all-wheel-drive electric vehicles, which leads to stability even at higher speeds under severe corners or bends. Equally important are advances made in battery technology alongside these other breakthroughs; wider ranges can now be covered with reduced charging durations achieved.

Taken together these innovations indicate that there is no limit whatsoever when it comes to improving upon what we already have thus paving the way for new ideas while ensuring continuous growth so far seen around hub motors technology towards robustness while meeting demands brought forth by the mobility sector that wants efficient power delivery methods capable of serving all kinds users whether commercial or personal among others such like those highlighted earlier.

How Riders Benefit From Advances In Motor Technology

Motor technology developments over time have greatly transformed the way people ride electric vehicles. Higher energy conversion rates mean that a rider can travel longer distances without having to recharge their batteries frequently, hence saving time and covering more ground effortlessly. The ability of a vehicle’s engine to output more torque enables fast take-offs, and climbing up hills becomes less strenuous due to increased power generation capacity, which facilitates quick acceleration even when going uphill. Similarly, the integration of complex control systems into an e-bike system provides better handling performance where such a motorbike responds quickly to rider inputs while still adapting its behavior according to surrounding conditions on a real-time basis.

Additionally, better thermal management designs ensure motors do not overheat easily thus making them more reliable over long periods since they rarely fail due to excessive heating. The use of lighter and stronger materials cuts down overall weight, thereby improving energy consumption rates and enhancing the handling characteristics of these machines even further. Another advantage is that modular motors simplify maintenance routines, hence less time wasted waiting for repairs or upgrades to be done by technicians who may not always be close by.

In conclusion, recent breakthroughs in motor technologies have significantly boosted the efficiency levels exhibited by electric vehicles at large, but this does not only result in savings made on fuel costs alone; rather, it also comes with improved safety standards as well as comfort levels during rides. These developments together make outdoor activities such as commuting daily workplaces much easier under any condition while still adding a fun factor into them through speediness among other things therefore contributing towards wider adoption & acceptability of this mode amongst the masses

Reference sources

-

Online Article - "Understanding the Efficiency of Hub Motors in Electric Vehicles"

- Source: ElectricDriveInsights.com

- Summary: This online article examines the effectiveness of hub motors in electric vehicles, highlighting their pros. It explains how simpler drivetrain design is achieved by the use of hub motors, better traction control and space integration within the wheel hub. The article gives technical views on advantages related to employment of hub motors for electric propulsion systems.

-

Academic Journal - "Hub Motors: A Comparative Analysis of Performance Metrics and Applications"

- Source: JournalofElectricEngineering.org

- Summary: Published in an academic journal, this research paper presents a comparative analysis of hub motors, highlighting their advantages in various applications. The journal article explores factors such as torque output, regenerative braking capabilities, and maintenance requirements, offering a detailed examination of the performance metrics that make hub motors advantageous in electric mobility solutions.

-

Manufacturer Website - "Enhancing Electric Bikes with Hub Motors: Advantages and Integration Solutions"

- Source: E-BikeInnovationsInc.com

- Summary: The website E-BikeInnovationsInc.com is a top producer of electric bike parts. One such piece is the hub motor. They list a number of reasons why these motors could be beneficial for someone’s e-bike, such as power delivery being better than ever before, having more torque, and being completely silent! In addition to this, they also talk about what makes them work well with other types/models that are out there, so if you’re trying to figure out which kind would be best, then look no further because everything can be found on their site.

Frequently Asked Questions (FAQs)

Q: Distinction Between Mid-drive and Hub Motor in Electric Bicycles

A: Mid-drive motors are placed at the crank of a bicycle, this gives an even center of gravity and good power efficiency throughout the gears of the bike. However, hub motors are installed on either front or rear wheels thereby giving power directly to the wheel. Generally, mid-drive motors are best suited for steep hills and rough terrains while hub motors provide a simpler solution that is often cheaper for flat terrains and casual riding.

Q: Why should one use a Hub Motor for an Electric Bicycle?

A: Among other things, one advantage associated with electric bicycles having hub motors is their ease of installation, which can be done on most standard bikes, thereby maintaining the existing transmission components of the bike. Secondly, they have lower initial costs and are considered more reliable due to fewer moving parts. Regenerative braking can also be enabled by hub motors, hence extending the range of rides by recharging batteries during braking.

Q: Are there any major disadvantages between a hub motor and a mid-drive motor?

A: Yes. Some drawbacks of hub motors include extra weight that is not supported by suspension systems located around wheels, thus affecting comfort when cycling, especially over bumpy surfaces, as well as handling capabilities on these uneven terrains. This kind may also prove less effective when climbing steep hills since it lacks gear utilization necessary for better efficiency in such situations; instead, it relies entirely upon torque produced at low speeds, which limits its ability to work efficiently under different conditions as mid-drives do.

Q: Can an ebike climb better with a mid-drive motor?

A: Yes indeed; In fact mid drive systems have been proven time after time again to be very efficient when it comes to hill climbing with e-bikes . Suchlike arrangements allow users shift through various levels depending on how steep or shallow an incline may appear much akin traditional bicycles making them easier conquer thus reducing strain put both on rider’s muscles and battery capacity used.

Q: What do you mean by unsprung weight, and why is it important with electric bike motors?

A: Unsprung weight refers to everything that is not supported by the suspension system of a vehicle (in this case, an e-bike), including wheels, tires, etc; this being so, reducing unsprung weights becomes crucial in as far as enhancing handling characteristics and overall ride comfort are concerned since less time will be taken by the shock absorbers when responding to changes in terrain elevation. However, hub motors increase unsprung mass, thereby jeopardizing control over such bikes, especially on rough grounds.

Q: What are the cost implications of using a mid-drive motor versus a hub motor for an e-bike?

A: Generally, due to their intricate design, integration with bike gears, and overall efficiency improvements, mid-drive motors tend to be pricier than hub motors. Nevertheless, the better performance output that follows higher initial investments cannot be overemphasized particularly when it comes to hilly or off-road commutes. At the same time, if simplicity during rides within cities is what matters most, then casual or urban riders may opt for cheaper but still effective solutions offered by Hub Motors.

Q: Can one retrofit either of these motors to an existing bicycle?

A: Yes, indeed! You can retrofit your old bicycle with a mid-drive or hub motor kit. However, please note that installation processes can vary greatly depending on which option you choose, some being much easier than others. Typically, all that is required when setting up such kits involves replacing one wheel and adding batteries/controllers – this applies more so with hubs (which are generally easier to install). On the other hand, mids are known for their complexity during installations because not only do they require major frame/drive modifications, but they also might call for professional help sometimes.

Q: What about maintenance — how does choosing between mid-drive and hub affect electric bike care?

A: Normally speaking, less maintenance will be needed by hub motors as compared to mid-drives since the former have fewer moving parts and don’t integrate with gear systems on bikes. This means that such systems could subject transmission components like chains, derailleurs, sprockets, etc., which already experience wear & tear due to increased torque passing through them under mid-drives, thus making regular checks very important if longevity plus optimum performances must be achieved with the latter types of e-bikes’ drives.